Industrialisation

Conception to industrialisation

At BeLink Solutions, we ensure a smooth transition from the design phase to production, thanks to a high-performance industrial site, controlled processes and rigorous supply chain management.

Whether you are developing a new product or looking to optimise an existing one, our Electronics Manufacturing Services teams support you at every stage of industrialisation.

Industrialisation is not simply mass production:

it is transforming a prototype into a reliable, repeatable and profitable electronic solution, while ensuring cost control, quality and production sustainability.

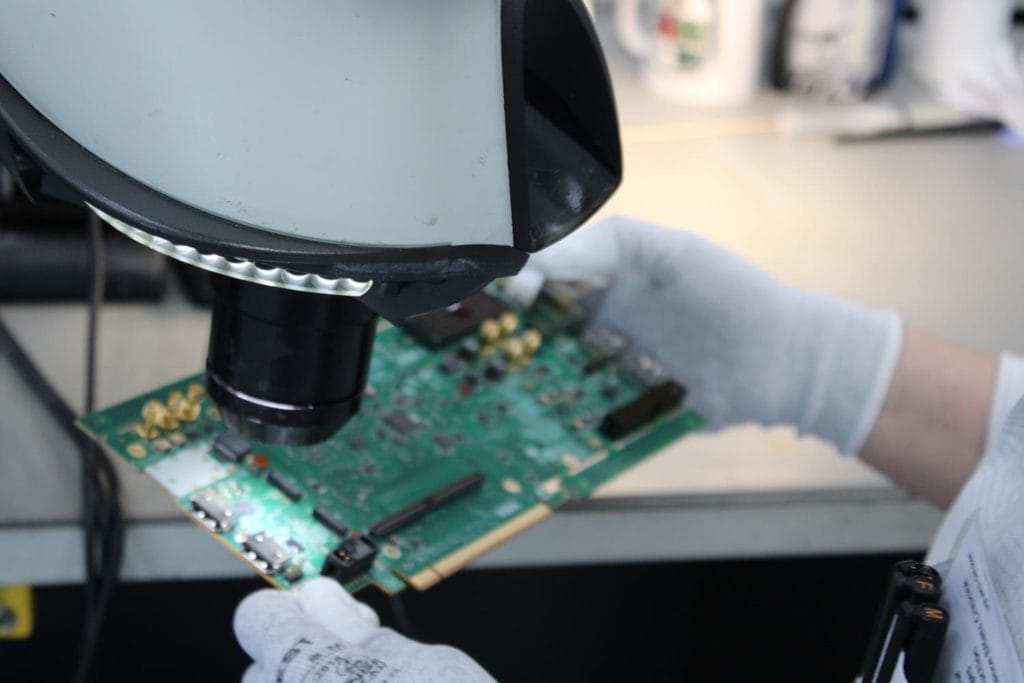

Industrial equipment

Our production site incorporates state-of-the-art equipment to guarantee our electronics company’s commitments, namely the reliability, repeatability and quality of your electronic boards, from the first series to industrial volumes.

- 5 SMD lines

- In-line checks at every stage: SPI (solder paste inspection), AOI (optical inspection), functional and optical testers

- Reflow or selective wave soldering, depending on product constraints

- Native traceability, from paste deposition to final testing

- Capacity of up to 10,000 boards/day or 10 million components placed daily

Certifications