Prototyping

At BeLink Solutions, we understand that your challenged deadline of execution is a key factor in the development of your electronics projects. We can manufacture your prototypes within a few days, while guaranteeing high quality and repeatability. This close collaboration between our Research & Development and our production team optimizes lead times and quality. Much more than just prototyping. We don’t just produce your prototypes: we support you in a continuous optimization process.

Thanks to our Project Management system tailored to prototypes and small series, we support you every step of the way to anticipate industrial challenges and ensure a smooth transition to mass production.

-

Box Build and assembly

Customizing assembly lines to meet your requirements.

-

Complex systems integration

Multi PCBA assembled product, harness, mechanical and specific connectors…

-

Robust flow chart of production

Assembly and testing to ensure reliability and compliance.

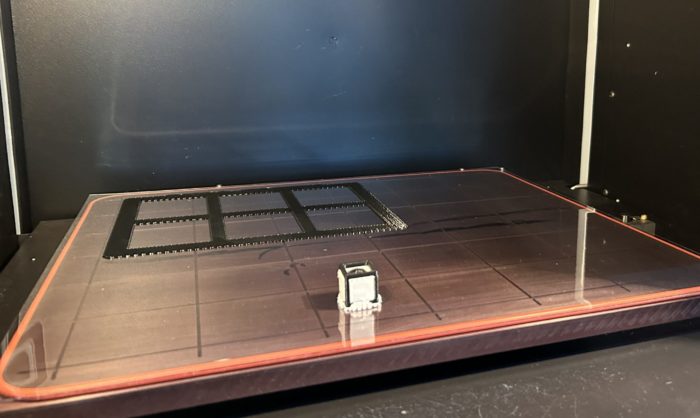

3D printing

Thanks to our additive manufacturing equipment, we accelerate your product development by creating custom parts for your prototypes, housing, and mechanical supports. We go beyond simple prototyping by directly integrating your electronic boards into printed housing and ensuring the complete wiring of your systems..

Control and testing in production

We integrate meticulous controls at each stage of prototyping, such as automatic optical inspection (AOI), X-ray, flying probe test, functional test to guarantee the reliability, repeatability and performance of your electronic boards, from the first samples.